What is PPU (Power Pack Unit) for SPMT, How does PPU work for Scheuerle Self-Propelled Modular Transporters

1. Description POWER PACK UNIT (PPU)

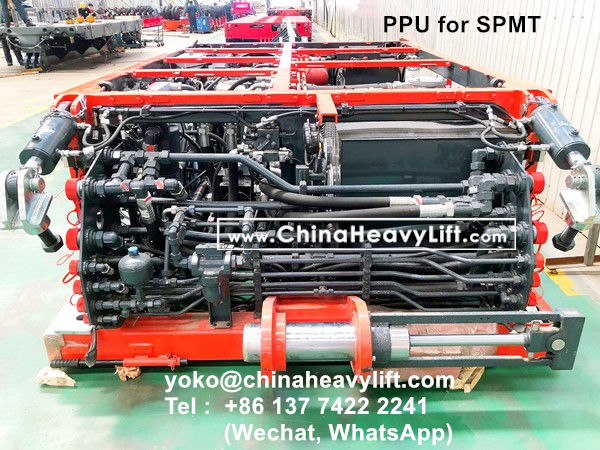

- The POWER PACK UNIT (PPU) consists of all drive components required to operate an SPMT combination. The PPU includes:

– the diesel engine with flanged hydraulic pumps

– coolers for cooling water, charge air and hydraulic oil

– hydraulic oil tank and diesel fuel tank

– switch boxes for electronic and electric control

– batteries, filters, control- and regulating valves - The Power Pack Unit is designed so that for transport container width is not exceeded and the PPU dimension is not higher than the loading height of the platform trailer

2. Frame

- The PPU frame mainly consists of welded square and angled profiles

- The sides are:

– clad with easily removable or foldable sound-absorbing alu plate sheedings

– equipped with welded-on scrape rails to protect the doors - At the front side:

– at the lower side the lamellar coupling with hydraulic coupling bolt is welded to be able to couple the PPU to the platform trailer

– at the upper side of the PPU there are hydraulic cylinders which fix the PPU by pressure bars to the platform trailer. Using this cylinder, the PPU can be tilted up to 12° in order to avoid ground contact when driving on ramps. In addition when the inclination is extreme, the PPU can be moved horizontally to prevent damage to the motor due to excessive inclination

– two storage boxes are integrated at the center on top. One of these is a Zarges box to store the remote control, in the second box the tools and the emergency control unit are included.

– one each on the right and on the left side a coupling plate is provided to supply the modules hydraulically and electrically. Here, corresponding connections are provided in order to connect several PPUís to electrical supply and control lines or to supply a parallel combination without PPU hydraulically / electrically - At the rear:

– the radiator is protected by a stable cooling grill

– the main switch board, pressure gauge and coupling point for the remote control is installed

– attachments are placed in order to be able to attach further mounting components to the PPU, such as additional heating aggregate, oil cooler, operating platform or operating seat - Upper side of the PPU

– cladded with walk-on aluminum riffle sheets and closed with latch locks.

– in the corners are provided corresponding anchor points which allow to load the PPUs alone or together with another platform trailer (4- or 6- axles) - Lower side

– equipped with 4 plastic rollers, allowing a shifting on firm ground

3. Powertrain

- User friendly and easy to maintain access by opening the lateral and / or upper maintenance flaps on top

- Flexible coupling, flange-mounted to the fly-wheel between hydraulic pumps and diesel engine. This protects the hydraulic pumps from damaging vibrations

- Complete drive train installed on vibration dampers

- Hydraulic pumps flanged one behind the other, providing maintenance-free access to the individual hydraulic pumps

- Spark arrestor integrated in the exhaust system of the internal combustion engine

- The exhaust pipe is guided laterally outside towards the upper side and can be dismantled for transport in order to maintain the transport width

4. Hydraulic System

- Hydraulic tank of stainless steel or coated with anti-corrosive coating, with integrated return filters and shut-off valves for the suction connections of the various hydraulic circuits

- Breathing- and venting of the hydraulic tank by desiccant cartridge

- Level indicator for minimum and maximum range led to the outside

- Hydraulic oil tank equipped with electric temperate and level sensor

- 4 pressure gauges for support pressure, with proportional valve for lifting/lowering situated below. Installed at the front right side of the PPU

- Pressure gauge at rear at the PPU for driving, steering and braking

- Hydraulically driven and speed-controlled fan of the coolers

5. Fuel System

- Fuel tank of stainless steel or coated with anti-corrosive coating

- Equipped with electric level sensor

- A fuel filter with water separator is installed in the fuel line leading to the diesel engine, which is protecting the injection system from contamination and water

6. Electrical System

- Electrical system in 24 V DC design

- All electrical / electronical switchgear and control units are installed vibration-proof in the switch boxes. They are made of stainless steel and with degree of protection IP 66

- Pressure compensation of the switch boxes by desiccant cartridge

- Easily accessible switch boxes, connection of the cable harnesses by plugs for easy repair or quick exchange

- Protected display for additional functions for error diagnosis and parameterization in the PPU

- Dashboard illumination in LED technology

- Coupling bolt in robust and durable technology

more detail of Power Pack Unit (PPU) for SPMT, please contact us ~