What is SPMT, How does SPMT work, China Manufacturer of Self-Propelled Modular Transporters

Description

- Electronic steering Self Propelled Modular Transporters(SPMT)

- The SPMT is especially useful wherever there’s no access for a crane or truck. They allow the load to be moved in multiple directions, and over distances longer than is practical with a hydraulic gantry or skidding system

- Characterized by the following features:

– electronic-hydraulic multidirectional steering

– module width in container dimensions for low transport costs and

– high payload capacity per axle line

Frame

- The SPMT platform is a closed frame construction and mainly consists of a trapeze-type main beam, parallel arranged bogie beams, transversally connected by the lateral booms to the main beam.

– standard main beam: for axle loads up to 48 ton, called M78 frame - At the front sides:

– lamellar coupling arranged below, with hydraulic coupling bolts at one side, to allow coupling of the platform in longitudinal direction. The hydaulic.coupling bolt can be operated from both sides.

– push bars arranged on top along the whole vehicle width with integrated centering supports in form of centering rings and centering pins, as well as boreholes to fix the bracing element.

– two lashing rings welded at each side with a capacity of 8.000 daN to tow the platform trailers during the transport to the operation site - Above or in the platform:

– metal sheet welded between the axles, above the outriggers for defined load introduction outside the main beam.

– load equipment integrated between the first and second, as well as the penultimate and last axle line and optional with shackle for easy loading by crane. Use as attachment point incl. capacity of 10.000 daN - Laterally along the platform:

– flange plate arranged above the axles, with integrated drilling pattern to couple the platform trailers parallel to each other; or for fixation of e.g. bolsters or other accessories to be attached to the platform. optional lashing point integrated in the flange plate with a lashing capacity of 13.400 daN in all directions

Wheel bogie

- The wheel bogie of the platform trailer consists of wheel bogies with drive axles, brake axles or running axles, arranged beneath the transverse beams and swivel-mounted by means of steering head bearing integrated in the transverse beam, supported by single-acting hydraulic cylinders. The bogie is designed for an axle load up to 48 tons. It is standardly installed in each platform trailer

- Maintenance-free pendulum bearing of the axles

- Maintenance-free swing arm bearing by joint bearing with grease lubrication

Solid Tire

- Heavy duty industrial filled sold tires, tire model: 355/65-15

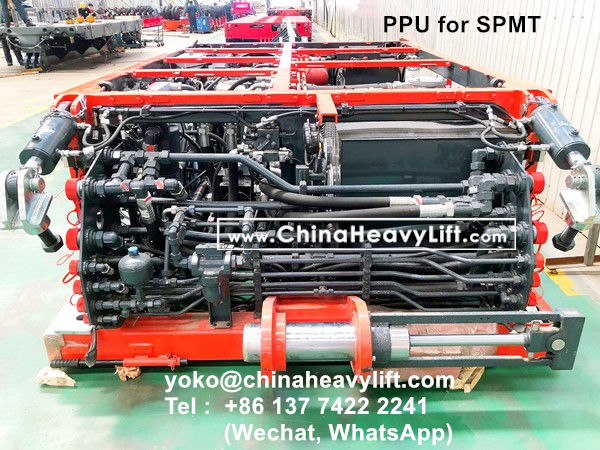

Hydraulic support and lifting

- Hydraulic axle compensation, hydraulic lifting device of the platform

- Pipe- and protection system in one circuit design in the hydraulic support system

- Each support cylinder can be removed from the system by a shut-off valve (ball valve) with help of an axle plug. After lowering the platform, the bogie can be mechanically arrested and after relifting the bogie is lifted

- Installed shut-off valves (ball valves) between each axle, this means the single bogies can be divided into 3 or 4 point support

Steering System (Electric – hydraulic Multi-Mode control)

- The bogies are steered by an electronic-hydraulic multidirectional steering (All Directional Electronic Steering System). It consists of the digital steering electronic with several steering programs and the hydraulic steering device, performed as double rack-gear

- Such way a steering angle of +/- 130° results

- For combinations in open compound, the steering pole is freely programmable

- The infinitely adjustable proportional valves on the bogies are activated by joystick which are installed on the remote control, thus the hydraulic steering drive is driven

- The steering propulsion is designed in such a way that during standstill and under full load steering and change of steering programs are possible

- The following steering programs are at disposal:

– all-wheel steering lengthwise

– all-wheel steering transverse

– diagonal steering lengthwise

– diagonal steering transverse

– truck steering front

– truck steering rear

– carousel steering

Brake

- Hydraulic-mechanic service- and parking brake

- The hydraulically actuated spring-accumulated brake cylinder and a slack adjuster are used to actuate the S-cams and the pad is pressed to the brake drum

- The required hydraulic release pressure is generated by the axial piston adjustment pump of the steering system in the PPU and the braking is performed via a finely dosed pressure control valve

- Due to the spring force in the brake cylinder, the combination is still safely braked and held in case of failure of hydraulic supply

more detail of Applications, Features and Benefits of Chinaheavylift SPMT, please contact us ~